An oft-quoted statistic is that most new businesses fail within the first year. According to the Small Business Administration, only around 30 percent of businesses survive a decade. And if you pull out figures from research on family-owned companies, survival rates quickly fall into the low single digits.

That’s what makes the three SMACNA member companies highlighted in this article all the more remarkable. As SMACNA celebrates its 75th anniversary as a national organization for sheet metal and HVAC contractors, it’s highlighting member companies that are celebrating some of their own milestones.

You would have a tough time finding an older continuously operating sheet metal contractor than Welsch Heating & Cooling Co. which has been continuously operating for more than 124 years. And while the Lynch Co. Inc. (100 years) or KSM Metal Fabrication (40 years) haven’t been around as long, they have both carved out a niche shielding them from economic fluctuations for many decades.

Many members could learn something from these successful contractors.

Welsch Heating & Cooling Co.

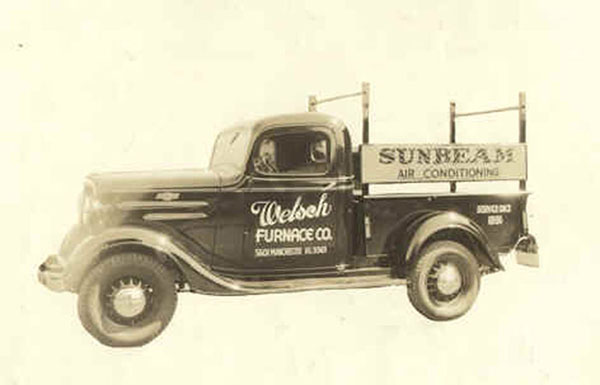

Few family-owned companies survive to the second generation, let alone the fourth. But Welsch Heating & Cooling Co. in St. Louis, is an exception. Now run by its 78-year-old president, George “Butch” Welsch, the 124-year-old firm is one of SMACNA’s most successful residential contractors. The company started out selling potbelly stoves out of a storefront in one of St. Louis’ historic

neighborhoods. It soon moved into coal furnace installation when those became the industry’s preferred heating method. By the 1940s, Welsch Heating was well-positioned to meet the demand for new technologies such as forced-air furnaces and air conditioning in the homes and buildings built in the years after World War II, which served as the base of Welsch Heating’s work for the next several decades. However, there was a downside to all that new-construction work, Welsch said. It was more susceptible to fluctuations in the economy, and every time the homebuilding industry suffered, the company would be severely impacted. He decided Welsch Heating needed to diversify its operations.

“Around 1990, I said I’m tired of these homebuilding cycles,” he recalled. “Let’s think about making a change.”

That change was a new focus on service and replacement work. Welsch Heating went from a company that was almost totally new construction, to one where it only comprises about 40 percent of its revenue — the rest is service and replacement. The company employs 20 service technicians and handles about 5,000 maintenance agreements annually.

Welsch Heating & Cooling Co. »

The Lynch Co. Inc.

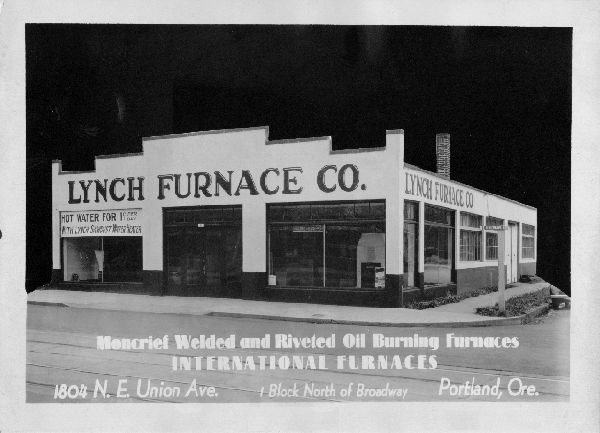

Since its founding by James R. Lynch in 1919, Portland, Ore.-based sheet metal contractor the Lynch Co. Inc. has survived recessions, depressions, wars and the evolution of its hometown from an industrial hub into one of the tech boom-towns of the Pacific Northwest.

The company started as a furnace and heating company. After the U.S. became involved in World War II, it joined the war effort by performing steel fabrication for the shipbuilding industry at yards in Portland and Vancouver, Wash. After the war, it saw success manufacturing oil and gas furnaces and sheet metal ductwork for industrial and commercial clients.

Today, the company’s list of industries served encompasses everything from agriculture to military, energy and fish and wildlife. General manager Pat Prentice said the company has never been one that simply does one thing well. Officials believe that expansion and evolution have been keys to its success.

“We’ve changed with the times and we’re diverse,” Prentice said. “We don’t just do one segment. This is the reason that we got into the structural steel fabrication as well. We do the sheet metal and the structural steel that supports the sheet metal as well. So, we’ll fabricate here in our shop. We’ll fabricate and erect. Whatever the customer wants,we’re here for them.”

KSM Metal Fabrication

KSM Metal Fabrication has evolved from its beginnings as Kerber Sheet Metal — an HVAC-focused company — in 1979 to its place today as KSM Metal Fabrication, which is one of the only SMACNA member companies involved in the aerospace industry.

It’s a niche that has allowed KSM to prosper as a go-to con-tractor that fabricates heat shields for aircraft brakes and wheels, along with other parts for the industry. Company president and COO Kathy Kerber said that when her father, Dan Kerber, founded KSM 40 years ago he didn’t have the family background or industry experience than many HVAC contractors have. What he did have was an accounting degree, and he learned the industry while handling the financials for a Troy, Ohio, plumbing and HVAC company.

Dan Kerber eventually bought the company’s HVAC operations, and a friend took over the plumbing division. That led to the founding of Kerber Sheet Metal on April 1, 1979. The entire company consisted of Dan Kerber and five employees.

It was not a great time to start a contracting business: The U.S. was teetering on the brink of recession and interest rates were in double digits.

“It was hard to compete in that economy,” Kathy Kerber said.

Fortunately, Kerber had a meeting with an engineer from the aero-space wheel and brake division that tiremaker B.F. Goodrich operated at the time. The engineers at B.F. Goodrich needed some specialized parts and wondered if Kerber’s sheet metal company could help make them. Kerber agreed to make the parts.

Early prototypes were cut using tin snips that had previously been used on ductwork. B.F. Goodrich engineers were so pleased, they asked Kerber to continue making parts for the company’s military and civilian aerospace projects. Kerber changed its focus from HVAC to the aerospace industry. Today, KSM parts are used on projects all over the country.

“We haven’t had our heating license in 15 years,” said Kathy Kerber, who became company president in 2012. In 2014, the company changed its name to KSM Metal Fabrication.

Today, KSM employs 25 people and their work is not only used in aerospace but also the food equipment and automotive industries.

In 2016 it received ISO 9001 certification for manufacturing from the International

Organization for Standardization, and in 2018 KSM received AS9100 (aerospace) certification for quality in that industry.